Home

“We have the equipment required for cost-efficient solutions”We offer a very high capacity and quality, short delivery times and good prices on laser cutting of steel, stainless steel, aluminum-, copper- and brass alloys, thanks to our advanced laser cutting and pressbrake machines. We also offer milling and lathe work for details where required. Whether it’s a prototype, a large or small production series or a single piece, we have the right equipment for cost-efficient solutions. Although most of our customers are in southern Sweden, we service a growing customer base throughout the entire EU and beyond due to increasing demand for our expertise in laser cutting. Our motto is to always be at the forefront of new technology. With a high production speed and precision equipment we can always offer our customers superior quality and short delivery times. We will always provide you with a detailed offer and estimated delivery time. DO NOT HESITATE TO CONTACT US! |

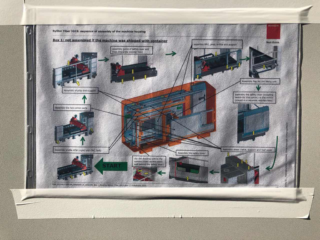

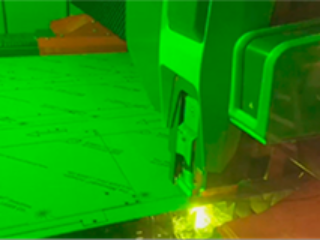

Laser Cutting

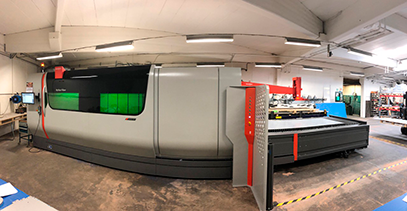

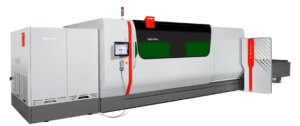

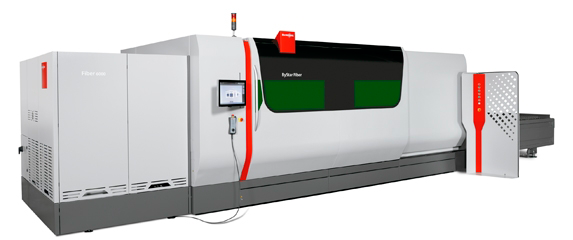

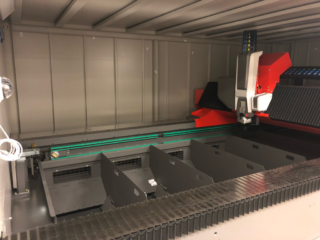

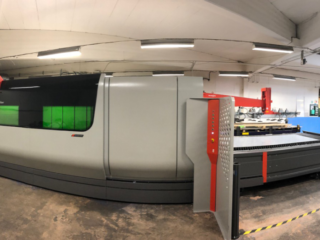

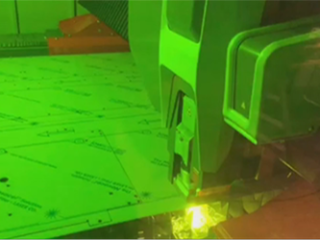

Bystronic Bystar Fiber 3015

High-speed cutting has several advantages. A low cost per piece and quicker delivery times. Precision is outstanding and laser cutting yields a burr-free result. Post-treatment is rarely required. Together these advantages provide a low production cost.

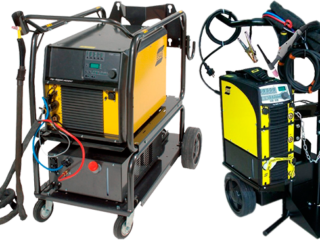

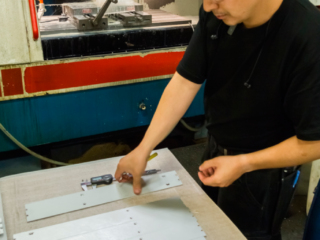

Pressbrake

Bystronic Xpert 200

Our latest acquisition with a sheet size capacity of 3000 mm and 200 tons of applied pressure. Together with Bysoft 7 and our laser-machine, it offers central control over the CAD/CAM production through the use of a single interface.

Amada HFP 170-3

Computer-driven. Sheet size capacity of 3000 mm and 170 tons of applied pressure.

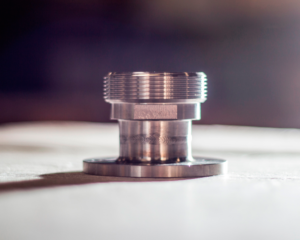

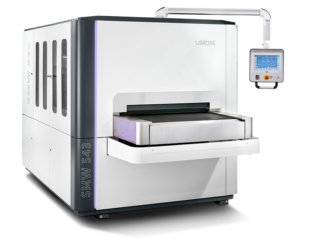

Milling – Lathe Work

MCFV – 100

For details requiring milling and/or lathe work, we offer this as a complement. Advanced multi-operation machines with a capacity of 25 different tools and near instant tool-switching, provides us with the capability to quickly and efficiently mill details with high precision.

Lathe Work

Lathe work with a rod feeding capacity up to 6 m and 40 mm diameter. Tool-switching capacity of 12 tools.

Owner / Director |

Owner |

|

Switchboard: +46(0)40-21 04 85 Opening hours: Monday-Thursdag Fridag Address: Rönnviksgatan 13, 213 74 Malmö, Sweden |

|

GDPR, General Data Protection Regulation In order for Kirsebergs Plåt & Mekaniska Verkstad AB to fulfill its commitment to customers and suppliers as well as its legal obligations, certain personal data is processed. The personal data we store and process are names, addresses, telephone numbers and e-mail addresses. We process your personal data in compliance with the General Data Protection Regulation (GDPR). We process your personal data on the ground of legal obligation, contractual necessity, consent and legitimate interests. We store and process your personal data only for as long as it is necessary for us to fulfill our obligations and commitments. Personal data is, however, erased no longer than 1 year after fulfilled obligations and/or commitment. We do not share your personal data with third parties. We are required to provide you with information as to which of your personal data we process and correct, update or erase your personal data upon your request. If you have any request, please see contact information below. GDPR Controller: Kirsebergs Plåt & Mekaniska Verkstad AB |